November 5th, 2008[Agiles 2008] Lean Lego Workshop in Buenos Aires

Continuing the series of conference reports, me and Frankie spend a day in Buenos Aires, Argentina to present a Lego(tm) Game we developed to teach some Lean practices and principles at Agiles 2008. The conference was held during the full week of 20-25 October, including three concurrent 2-day Certified Scrum Master trainings and Mary and Tom’s 2 day course on Lean Software Development.

Unfortunately, we were not able to stay for the whole week, but spending one day gave us a pretty good impression of how Agile is growing in Latin America. The conference had about 400 participants during these 5 days and they had to reject some of the 900 interested due to logistics constraints. As happened in the US and Europe, the major driver for Agile adoption is being Scrum and, as more people start adopting it, the more problems are uncovered about how they can improve on the “technical” engineering practices.

Mary’s opening keynote was exactly about that: how important it is to look at the engineering side of Agile to make its success sustainable. This was the same talk she gave at Agile 2008, highlighting the successes and failures (Plank Roads) of our short software engineering history. I thought it was much better than the last time I saw it, and she managed to convey her message in a much more clear way: focusing on processes/life-cycle has been fragile, while strong technical and engineering practices has shown success throughout our history.

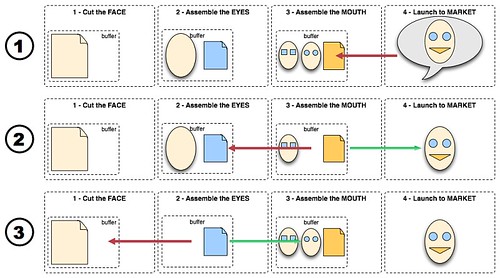

Our workshop went really well: the number of participants and their level of knowledge on Lean matched exactly what we had in mind when we developed it. I’m not going to describe the dynamics of the session, because Frankie already did a good job in doing that. Suffice it to say that the feedback we received was great and that we already have some changes to make it even better. I’m also making the slides available here, although you would have to participate on the hands-on exercises to fully understand it.

I think the overall message of our session was to show how some of the Lean practices work in practice, but also highlight the importance of Systems Thinking and the principles behind the practices. Blindly applying a practice may give you marginal results, but to fully embrace a Lean philosophy you need to keep learning and improving. There’s not an easy recipe to success.

After a good lunch (with Argentinian steak and some Brazilian friends), we went back to the venue and didn’t have a lot of time to watch any other session, so we rushed to the airport. Next year’s conference is promissing to be even bigger, and besides wanting to stay for the whole week, I hope to see more Brazilians sharing their Agile experiences with the Latin American community.

Twitter

Twitter LinkedIn

LinkedIn Facebook

Facebook Flickr

Flickr